Blog

Top Tips for Maintaining Our Machines for Optimal Performance and Longevity

In today's fast-paced industrial landscape, the performance and longevity of our machines are paramount to maintaining efficiency and productivity. As noted by leading expert Dr. Emily Carter, a renowned mechanical engineer, "The key to maximizing the lifespan of our machines lies in proactive maintenance practices that not only prevent breakdowns but also enhance operational excellence." With the right strategies in place, businesses can ensure that their machinery operates at optimal levels, ultimately contributing to overall success.

Effective maintenance requires a balanced approach that integrates regular inspections, timely repairs, and adherence to manufacturers’ guidelines. By prioritizing these practices, organizations can mitigate the risk of unexpected downtimes and costly repairs, a sentiment echoed by Dr. Carter, who emphasizes, "A well-maintained machine is not just a benefit; it's a fundamental necessity in a competitive market."

As we delve into essential tips for maintaining our machines, it becomes clear that the health of our machinery directly reflects our commitment to quality and efficiency. Understanding and implementing these maintenance tips will empower companies to safeguard their investments and ensure that our machines remain reliable assets for years to come.

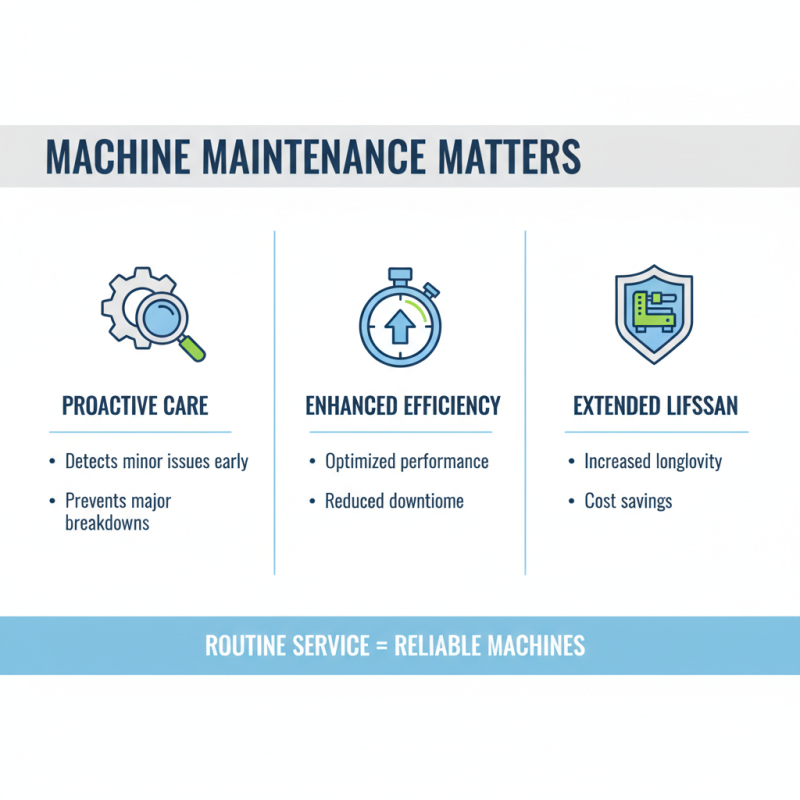

Importance of Regular Maintenance for Machine Performance

Regular maintenance is crucial to ensure optimal performance and longevity of machines. When machines are routinely serviced, minor issues can be detected and addressed before they escalate into major problems. This proactive approach not only enhances machine efficiency but also extends their operational life. For instance, regularly checking and replacing worn-out parts can prevent unexpected breakdowns that could lead to costly repairs and downtime.

In addition to preventing breakdowns, regular maintenance contributes to maintaining high-quality output. Machines that are well-maintained operate more smoothly, producing consistent results. This reliability is essential in many industries where precision and quality directly impact productivity and profitability. By investing time and resources in a structured maintenance schedule, operators can maximize their machines' capabilities and ensure they function at their best for years to come.

Key Maintenance Practices to Enhance Machine Longevity

Effective maintenance practices are crucial for enhancing the longevity of industrial machines, as they contribute significantly to operational efficiency and cost savings. According to a report by the International Association for Maintenance Professionals, preventive maintenance can reduce equipment failure by up to 40%. Regular checks and services not only extend the lifespan of machines but also minimize downtime, which can be detrimental to production lines. For instance, implementing a robust inspection schedule can help identify wear and tear before it leads to critical failures, enabling companies to plan maintenance activities during off-peak hours.

In addition to routine inspections, keeping detailed maintenance records is essential for optimizing machine performance. A study from the Asset Management Council reveals that organizations utilizing software for asset tracking see a 20% increase in machine availability and significantly lower operating costs. By analyzing these records, maintenance teams can identify patterns and trends that indicate potential issues, allowing for data-driven decisions on when to perform repairs or replacements. Engaging in training programs for operational staff on proper machine handling and maintenance also fosters a culture of care, ultimately contributing to the machines’ sustainable performance and extending their operational life.

Identifying Common Issues and Their Solutions in Machine Care

Maintaining machines is crucial for ensuring their efficiency and extending their lifespan. One common issue that arises in machine care is the accumulation of dust and debris, which can lead to overheating and mechanical failure. Regular cleaning of components, especially cooling systems, is essential. Utilizing compressed air and appropriate cleaning tools can help eliminate buildup, thereby maintaining optimal airflow and temperature control.

Another prevalent concern is insufficient lubrication, which can cause increased friction and wear on moving parts. It is vital to follow a consistent lubrication schedule, using the correct type of oil or grease for the specific machine. Monitoring levels and applying lubricant as needed can prevent costly repairs and downtime. Additionally, operators should be trained to identify early signs of wear or malfunction, such as unusual noises or vibrations, to address issues before they escalate, ensuring smoother operation and longevity of the equipment.

Top Tips for Maintaining Our Machines for Optimal Performance and Longevity - Identifying Common Issues and Their Solutions in Machine Care

| Issue | Symptoms | Recommended Solutions | Frequency of Check |

|---|---|---|---|

| Overheating | Excessive heat, unusual smells | Clean cooling vents, replace filters | Weekly |

| Unusual Noises | Grinding, squeaking, or rattling sounds | Inspect bearings and lubrication | Monthly |

| Vibration | Excessive shaking or wobbling | Check mounting and alignment | Monthly |

| Poor Performance | Slower operation than normal | Calibrate settings, clean components | Bi-weekly |

| Leaks | Fluid pooling under machines | Inspect seals and fittings | As needed |

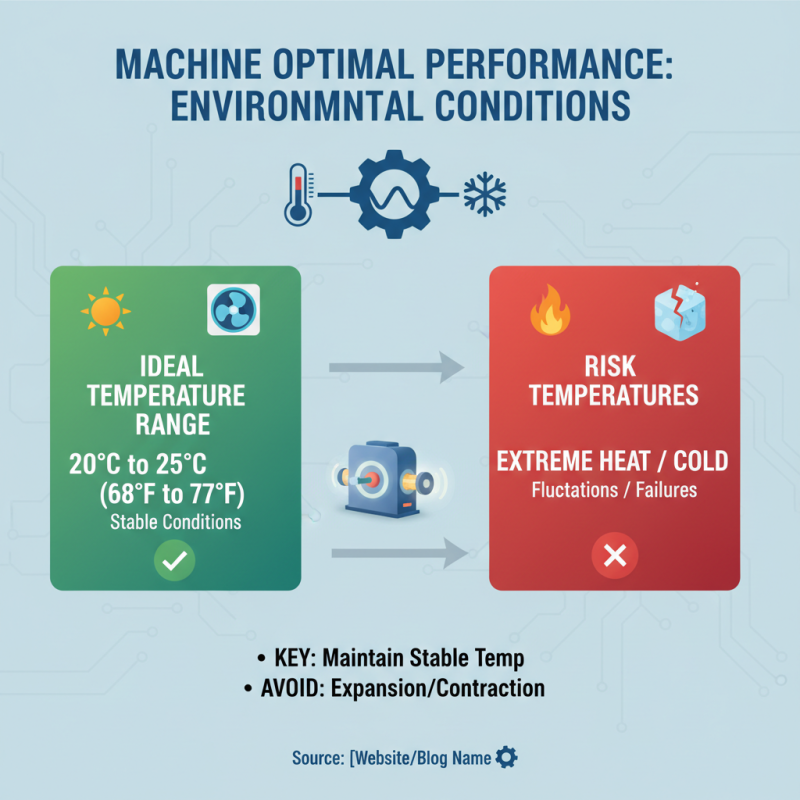

Best Environmental Conditions for Optimal Machine Operation

The optimal performance of machines is significantly influenced by the environmental conditions in which they operate. Maintaining a stable temperature range is crucial; extreme heat or cold can lead to overheating or freezing of components, respectively. Ideally, most machines operate best in environments where the temperature remains between 20°C and 25°C (68°F to 77°F). Conversely, fluctuations outside this range can cause materials to expand or contract, potentially leading to mechanical failures or reduced efficiency over time.

Humidity levels also play a vital role in the longevity of machines. Excessive moisture can lead to corrosion and electrical failures, while overly dry conditions may cause static electricity build-up, damaging sensitive electronic components. Keeping humidity between 30% and 50% is generally advisable. Providing adequate ventilation can further mitigate risks associated with stagnant air or heat accumulation, ensuring that machines remain cool and operational, thus enhancing their performance and lifespan.

Additionally, cleanliness in the operational environment cannot be overlooked. Dust, dirt, and debris can infiltrate vital machine components, causing wear and tear that may hinder functionality. Regularly inspecting the workspace and implementing effective cleaning protocols will help protect machines from unnecessary damage, ensuring they can operate at optimal performance for years to come.

Scheduling and Documenting Maintenance Activities Effectively

Effective scheduling and documentation of maintenance activities are crucial for maximizing the performance and longevity of machines. According to a report by the International Society for Asset Management, organizations that implement a proactive maintenance strategy can reduce their downtime by up to 30%. This highlights the importance of not only having a maintenance schedule but also ensuring that it's meticulously documented. By keeping accurate records of when maintenance was performed, the types of services rendered, and any issues noted, companies can better track patterns and anticipate future repairs, ultimately extending the operational life of their equipment.

One key tip for effective scheduling is to adopt a preventive maintenance approach rather than relying solely on reactive measures. This can be achieved by utilizing software tools that alert you when maintenance is due, ensuring that no service is overlooked. Furthermore, maintaining a checklist for each machine can streamline the documentation process, ensuring that all necessary inspections are completed systematically.

Additionally, regular reviews of maintenance documentation can provide insights into the machine's performance and common failure points. Data from the Reliability Centered Maintenance (RCM) framework suggests that organizations that analyze historical maintenance records can improve their maintenance planning efficiency by up to 25%. By dedicating time to review and adapt your maintenance scheduling process based on documented activities, you ensure your machines operate at their peak performance while minimizing unexpected failures.

Related Posts

-

Unlocking the Benefits of the Best Single Brew Coffee Machines for Perfect Mornings

-

Discover the Future of Brewing: Innovative Coffee Machines Transforming Your Morning Routine

-

The Future of Automated Refreshments Exploring Coffee and Tea Vending Machines

-

Innovative Solutions for Maximizing Profits with Best Coffee Vending Machines

-

Top 10 Coffee Maker Machines for Perfect Brew at Home in 2023

-

Top Coffee Maker Machines: Your Ultimate Guide to Brewing the Perfect Cup